Servicing

With our knowledgeable, highly trained Service engineers supported by in house apprentice trained technical staff and a technical resource library covering our products, Asquith Butler are able to provide the following options to aid your production:

Full Machine Servicing. We can carry out routine planned maintenance on your machine offering packages tailored to your requirement from simple machine visual inspections and condition reports through to full geometry checks and adjustments with Axes Laser positional calibration.

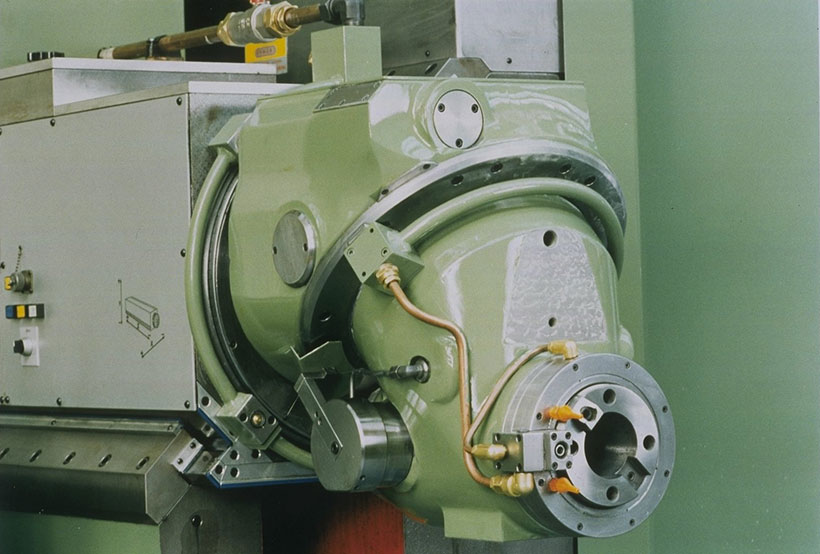

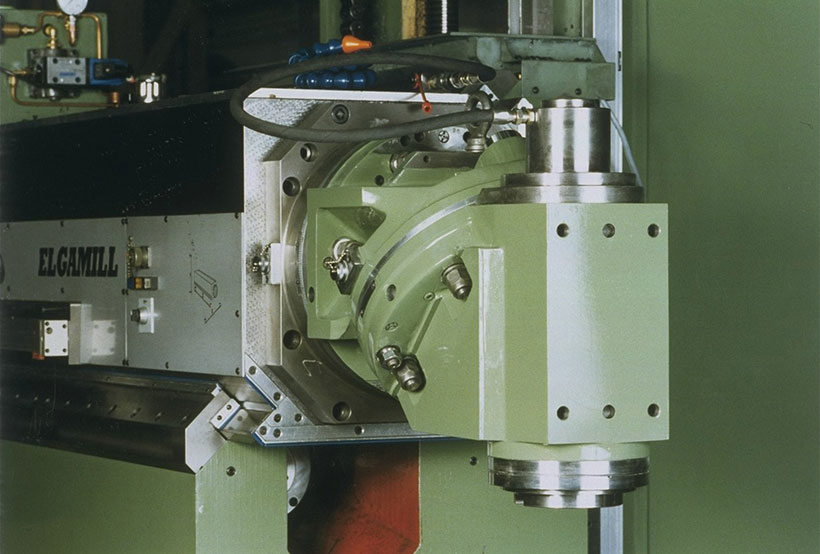

Machining head service. We can perform a periodic machining head service including stripping and re-greasing as part of a regular planned machine service or we can remove your machine head and fit a hire unit whilst yours is being serviced at our purpose built facility. This has the advantage of minimising production downtime.

Subject to availability and conditions

Machine breakdown repairs. We can respond to machine breakdowns whether from equipment failure or accidental damage to minimise machine downtime

Advantages

- Provides Records of maintenance for Health and Safety purposes

- Machine availability can be improved.

- Proof of machine reliability /accuracy can be provided to clients.

- Provides a history for the machine potentially increasing asset resale value.

- Unexpected machine failures can be minimised.

- Machine usable life span can be extended.

- Developing issues are highlighted early so planned repair and the associated downtime can be built into production schedules.